Description

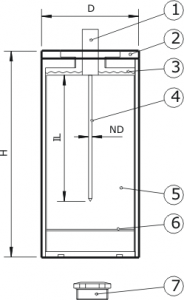

The hart of the CRC cylinders is a specially manufactured amorphous plastic reference material (5). (See Figure 1). Contrary to other plastics, this material does not have any directionally dependent thermal properties. In the plastic material a hole is drilled (4), with the approximate outer dimensions (ND Needle Diameter and IL Insertion Length) of the needle that needs to be calibrated.

The plastic material is incorporated in a metal protection casing (2). A plug (7) is provided for sealing purposes. In order to guarantee perfect contact between needle (1) and reference material (5), the metal casing is filled with a fluid, glycerol (3). An additional hole (6) is provided in order to be able to perform checks of material stability with thin needle probes. The user is recommended to send the CRC to Hukseflux for a check of material stability every 5 years.

The plastic material is incorporated in a metal protection casing (2). A plug (7) is provided for sealing purposes. In order to guarantee perfect contact between needle (1) and reference material (5), the metal casing is filled with a fluid, glycerol (3). An additional hole (6) is provided in order to be able to perform checks of material stability with thin needle probes. The user is recommended to send the CRC to Hukseflux for a check of material stability every 5 years.

Specifications

| Test method | ASTM D 5334-00 and D 5930-9, IEEE Std 442-1981 |

|---|---|

| Temperature range | 0 – 60 °C |

| Thermal conductivity of reference | 0.2 W/mK (nominal value) |

| Traceability | to NPL National Physical Laboratory, United Kingdom |