Description

Description

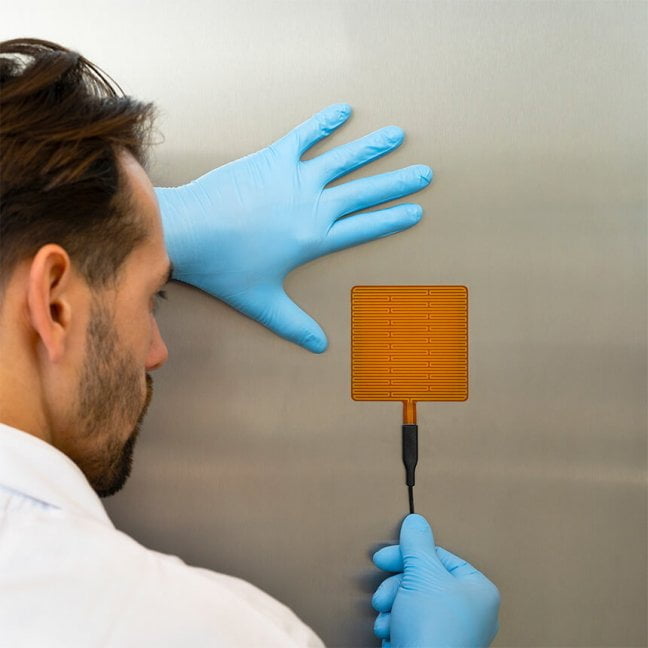

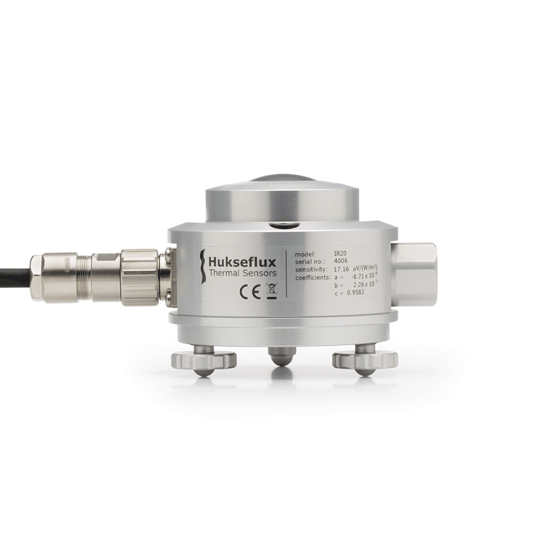

FHF05SC series are sensors for general-purpose heat flux measurement, combined with a heater. It is used when the highest level of quality assurance is required and for long-term heat flux measurements. It is thin, flexible and versatile. FHF05SC series measures heat flux through the object in which it is incorporated or on which it is mounted, in W/m2. The sensor within is a thermopile. This thermopile measures the temperature difference across FHF05SC’s flexible body. A type T thermocouple is integrated as well to provide a temperature measurement. The thermopile and thermocouple are passive sensors; they do not require power.

Multiple small thermal spreaders, which form a conductive layer covering the sensor, help reduce the thermal conductivity dependence of the measurement. With its incorporated spreaders, the sensitivity of FHF05SC series is independent of its environment. Many competing sensors do not have thermal spreaders. The passive guard area around the sensor reduces edge effects and is also used for mounting.

Looking only for heat flux and temperature measurement without the heater: see our FHF05 series heat flux sensors.

Unique features and benefits:

- heater for self-test

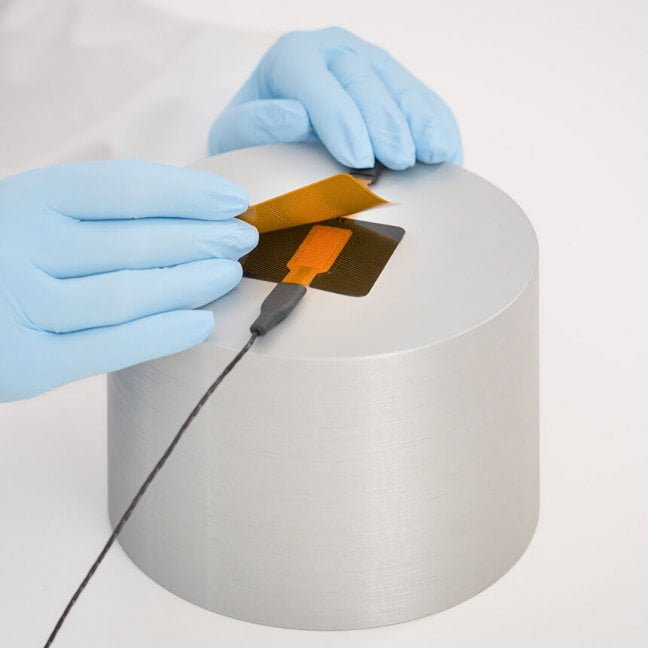

- flexible (bending radius ≥ 15 x 10⁻³ m)

- low thermal resistance

- wide temperature range

- fast response time

- integrated type T thermocouple

- robustness, including potted connection block, may be used as strain relief

- IP protection class: IP67 (essential for outdoor application)

- integrated thermal spreaders for low thermal conductivity dependence

Using FHF05SC series is easy. For heat flux measurements, it can be connected directly to commonly used data logging systems. The heat flux in W/m2 is calculated by dividing the sensor output, a small voltage, by the sensitivity.

The sensitivity is provided with FHF05SC series on its product certificate. When used under conditions that differ from the calibration reference conditions, the FHF05SC series sensitivity to heat flux may be different than stated on its certificate. See the user manual for suggested solutions.

Make sure your data acquisition accepts type T thermocouples before doing temperature measurements.

Measuring heat flux, users may wish to regularly check their sensor performance. During use, the film heater is activated to perform a self-test.

The heat flux sensor response to the self-test results in a verification of sensor performance. Implicitly also cable connection, data acquisition, thermal connection of sensor to its environment and data processing are tested. Heat flux sensors are often installed for long periods of time. Using self-testing, the user no longer needs to take sensors to the laboratory to verify their stable performance. In a laboratory environment, using a metal heat sink, you may even perform a formal calibration. The heater has a well characterized and traceable surface area and electrical resistance.

Equipped with a connection block, which may serve as strain relief, and with potted protective covers on both sides so that moisture does not penetrate, FHF05SC series has proven to be very robust and stable.

FHF05SC series calibration is traceable to international standards. The factory calibration method follows the recommended practice of ASTM C1130 – 21.

Requirements for data acquisition and control:

- for heat flux: one millivolt measurement

- for heater voltage: one voltage measurement

- optional, for heater current: one current measurement or voltage measurement over a resistor

- for switching the heater current on and off: one relay with 12 VDC nominal output

Specifications

| Measurand | heat flux, temperature |

|---|---|

| Outer dimensions foil with guard | (50 x 50, 85 x 85) x 10⁻³ m |

| Measurement Range | (-10 to +10) x 10³ W/m² |

| Sensitivity (nominal) | : |

| FHF05SC-50X50 | 13 x 10⁻⁶ V/(W/m²) |

| FHF05SC-85X85 | 50 x 10⁻⁶ V/(W/m²) |

| Temperature sensor | type T thermocouple, IEC 60584-1:2013 class 2* |

| Thermal spreaders | Included |

| Rated bending radius | ≥ 15 x 10⁻³ m |

| Rated load on cable | ≤ 1.6 kg |

| Sensor thermal resistance | 24 x 10⁻⁴ K/(W/m²) |

| Sensor thickness | 0.7 x 10⁻³ m |

| Uncertainty of calibration | ± 5 % (k = 2) |

| Rated temperature range – continuous use | -40 to +120 °C** |

| Rated temperature range – short intervals | -160 to +150 °C** |

| IP protection class | IP67*** |

| Standard wire length | 2 m |

| FHF05SC-50X50 | 120 Ω (nominal) |

| FHF05SC-85X85 | 40 Ω (nominal) |

| Heater power supply | 12 VDC |

| Options |

|

Frequently asked questions

How to measure heat flux?

Heat flux sensors measure energy flux onto or through a surface in [W/m²].

The source of the heat flux may be:

- conduction

- radiation

- convection

Convective and conductive heat transfer are associated with a temperature difference. Heat always flows from a source to a sink, from a hot to a cold environment. Convective and conductive heat flux is measured by letting this heat flow through the sensor. Radiative flux is measured using heat flux sensors with black absorbers. The absorbers converts radiative to conductive energy. Hukseflux started in 1993 with sensors for measurement of heat flux in soils and on walls. In the course of the years, we have added specialised sensors and systems for many other applications.

Heat flux sensors manufactured by Hukseflux are optimised for the demands of different applications:

- rated temperature range

- rated heat flux range

- sensitivity

- response time

- chemical resistance, safety requirements

- size, shape and spectral properties

Hukseflux is the world market leader in heat flux measurement. If you do not understand what heat flux is please refer to our informational article on heat flux.

What is a heat flux sensor?

To learn more about what a heat flux sensor is, check out our page called What is a Heat Flux Sensor?

What matters most when measuring with a heat flux sensor?

There are quite a few general considerations when starting a heat flux measurement.

- Representativeness in time and space; average!

A heat flux sensor measures at a certain location. Is this location representative of what you need to measure? If possible, use a relatively large sensor, rather than a small one, and consider use of multiple sensors. Thermal processes often have large time constants; instantaneous measurements may be misleading. Average to get the full picture. - Optical properties

When heat flux sensors also measure radiation, pay attention to the surface color. If needed paint the sensor surface. Please mind that shiny metallic surfaces reflect both infra-red and visible radiation. Paints may have different colors in the visible range, but are usually “black” absorbers in the far-infra-red. - Sensor thermal resistance

A heat flux sensor distorts the local heat flux. In order to minimize this effect, use the sensor with the lowest possible thermal resistance. - Edge effects

A heat flux sensor locally distorts the heat flow pattern, in particular around the edges of the sensor. A passive guard, i.e. a non-sensitive part around the sensor is essential to avoid errors due to edge effects.

There are more characteristics that matter. Please find them in our white paper on heat flux fundamentals and applications.

Which sensor(s) to use for surface energy flux measurement?

Hukseflux manufactures a range of sensors for surface energy flux measurements. All have proven reliability.

These state-of-the-art sensors are made for the global fluxnet community:

- NR01 is a market leading 4-component net radiometer.

- HFP01 and HFP01SC measure soil heat flux.

- STP01 offers an accurate temperature profile measurement.

- TP01 is the leading sensor for soil thermal conductivity.

Sensors made by Hukseflux are designed for compatibility with most common datalogger models. For many models we have example programs and wiring diagrams available.

How to measure R-value and U-value of buildings?

On-site measurements of thermal resistance, R, are often applied in studies of buildings. Alternatives are to measure its inverse value, the thermal conductance which is called the Λ-value, or the thermal transmittance which includes ambient air boundary layer thermal resistance, the U-value. The measurements of R are based on simultaneous time averaged measurement of heat flux Φ and differential temperature, ΔT, (using two temperature sensors on each on a different side of the wall).

R = ΔT / Φ

Hukseflux provides a range of sensors and measuring systems for use in measurement of the energy budget of buildings and characterization of construction materials.

HFP01 heat flux sensor and TRSYS01 measuring system are widely used for on-site measurements on walls, windows and other construction elements in building physics.

- HFP01 can be used for in-situ measurement of building envelope thermal resistance (R-value) and thermal transmittance (H-value) according to ISO 9869, ASTM C1046 and ASTM 1155 standards. HFP01 is the world’s most popular sensor for heat flux measurement in the soil as well as through walls and building envelopes. HFP01 measures heat flux through the object in which it is incorporated or on which it is mounted, in W/m². More information? Visit the HFP01 product page.

- TRSYS01 is a high-accuracy system for on-site measurement of thermal resistance, R, thermal conductance, the Λ-value, and thermal transmittance, the U-value, of building envelopes. TRSYS01 is mostly used for measurements according to standard practices of ISO 9869 and ASTM C1155 / C1046. The system is equipped with high-accuracy electronics, two heat flux sensors of model HFP01 as well as two pairs of matched thermocouples. The two measurement locations provide redundancy, leading to a high level of confidence in the measurement result. The high accuracy of the heat flux sensors and temperature difference measurements ensures that TRSYS01 continues measuring when other systems no longer perform; in particular at very low temperature differences across the wall.

Where can I find complete heat flux measuring systems?

Hukseflux, market leader in heat flux measurement, offers both sensors and systems.

These measuring systems typically include a Measurement and Control Unit and one or more sensors for measuring heat flux as well as other measurands, such as temperature and humidity. Examples are the TCOMSYS01 Hot Cube thermal comfort measuring system, including a TCOM01 sensor, and the TRSYS01 measuring system, incorporating two HFP01 heat flux sensors and two pairs of matched thermocouples.

Cannot find what you are looking for? Please contact us.